Robot Layout Optimization

Workload-driven warehouse layout optimization

In modern manufacturing, the physical arrangement of robots within a production line can dramatically impact both efficiency and energy consumption. Even small layout improvements can lead to significant cost savings at scale. Our research addresses this challenge with an innovative approach called Multi-Robot Layout Optimization (MRLO).

The Challenge of Robot Layout Design

Determining the optimal placement of robots in a production environment is surprisingly complex. The layout affects how robots coordinate with each other, how they navigate around physical constraints, and how efficiently they can complete their assigned tasks.

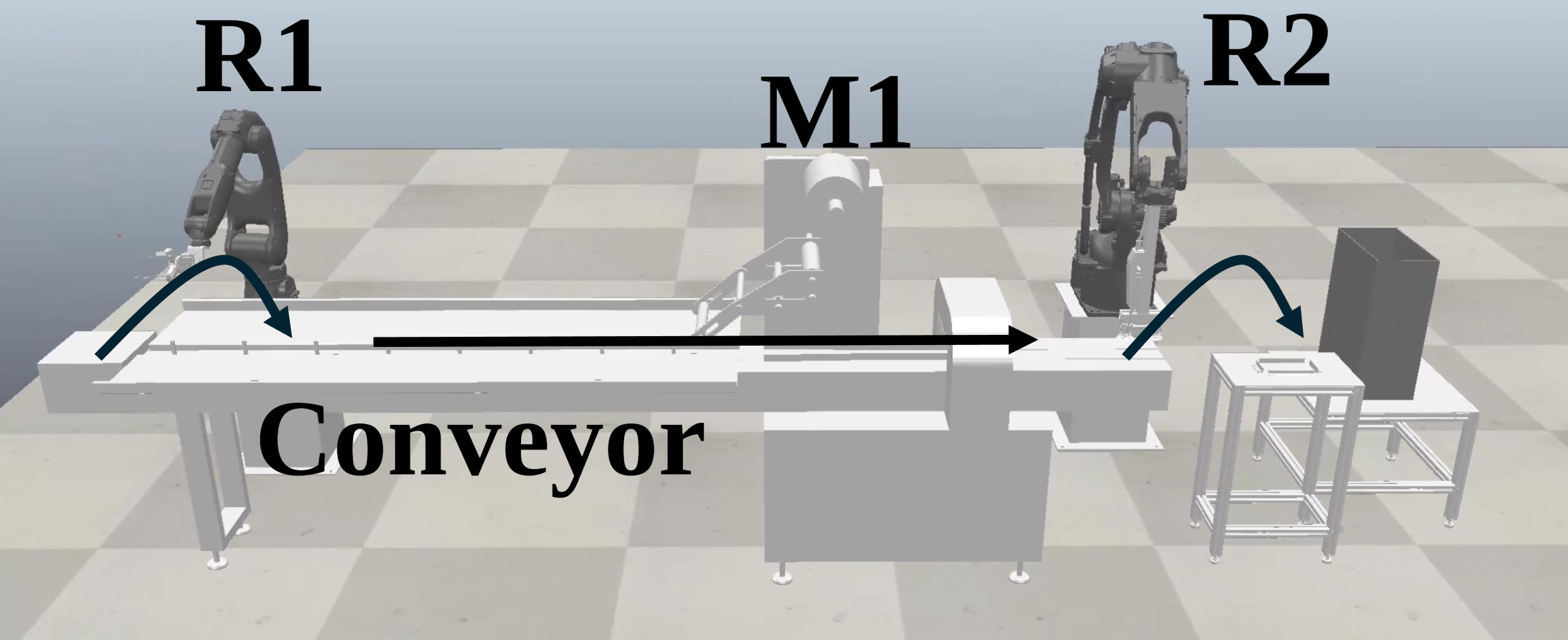

Poor robot positioning creates unnecessary bottlenecks. For example, in a dual-robot assembly line, if Robot A feeds parts to Robot B but they’re poorly positioned relative to each other, one robot might need to wait for the other to complete its motion before proceeding, even when their tasks could theoretically overlap.

Our Approach: The MRLO Framework

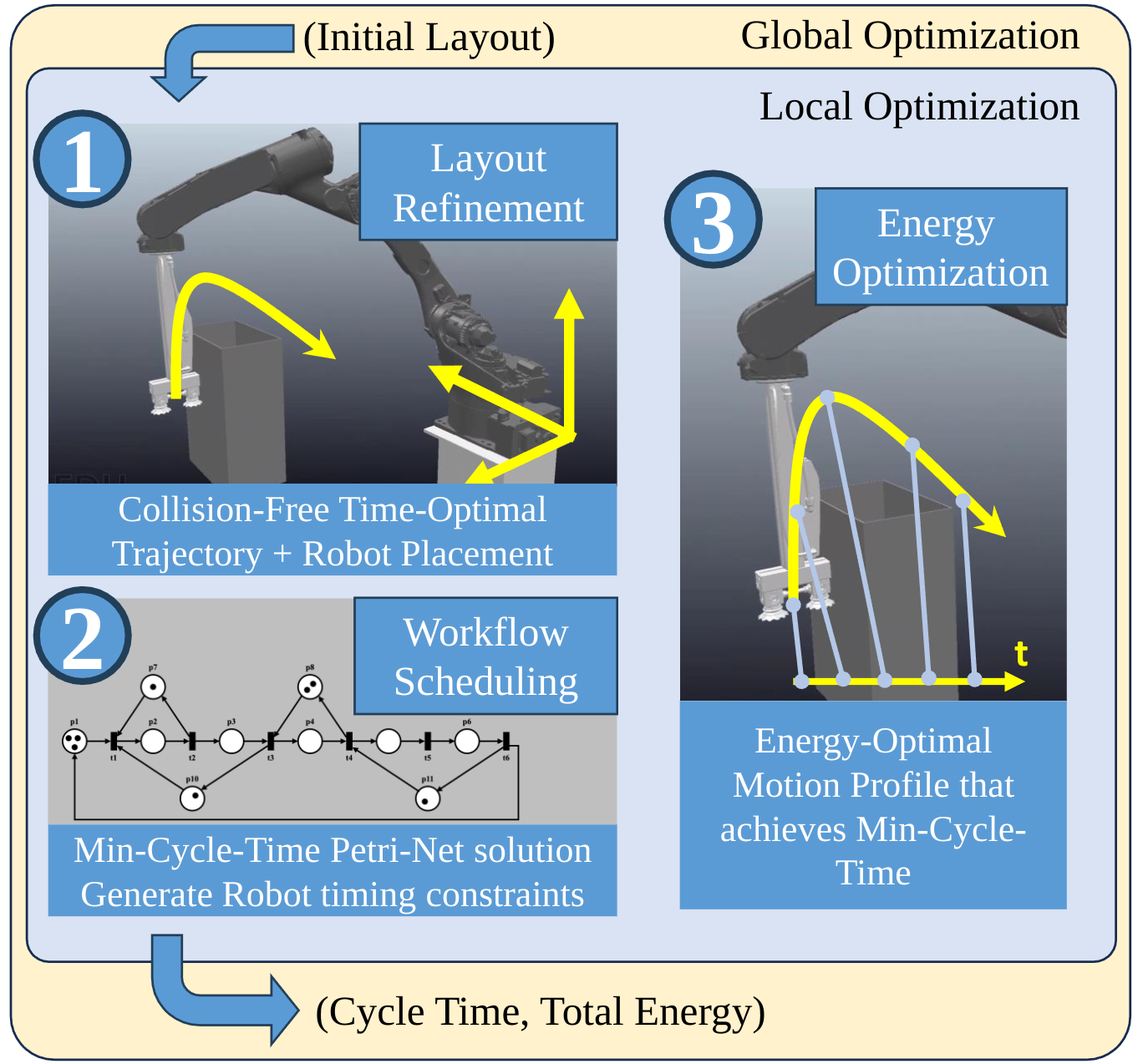

The Multi-Robot Layout Optimization (MRLO) framework tackles these challenges through a sophisticated two-level optimization approach:

-

Global Optimization: Uses an evolutionary algorithm called Covariance Matrix Adaptation Evolution Strategy (CMA-ES) to efficiently search through possible robot layouts

-

Local Optimization: For each candidate layout, quickly refines the solution through:

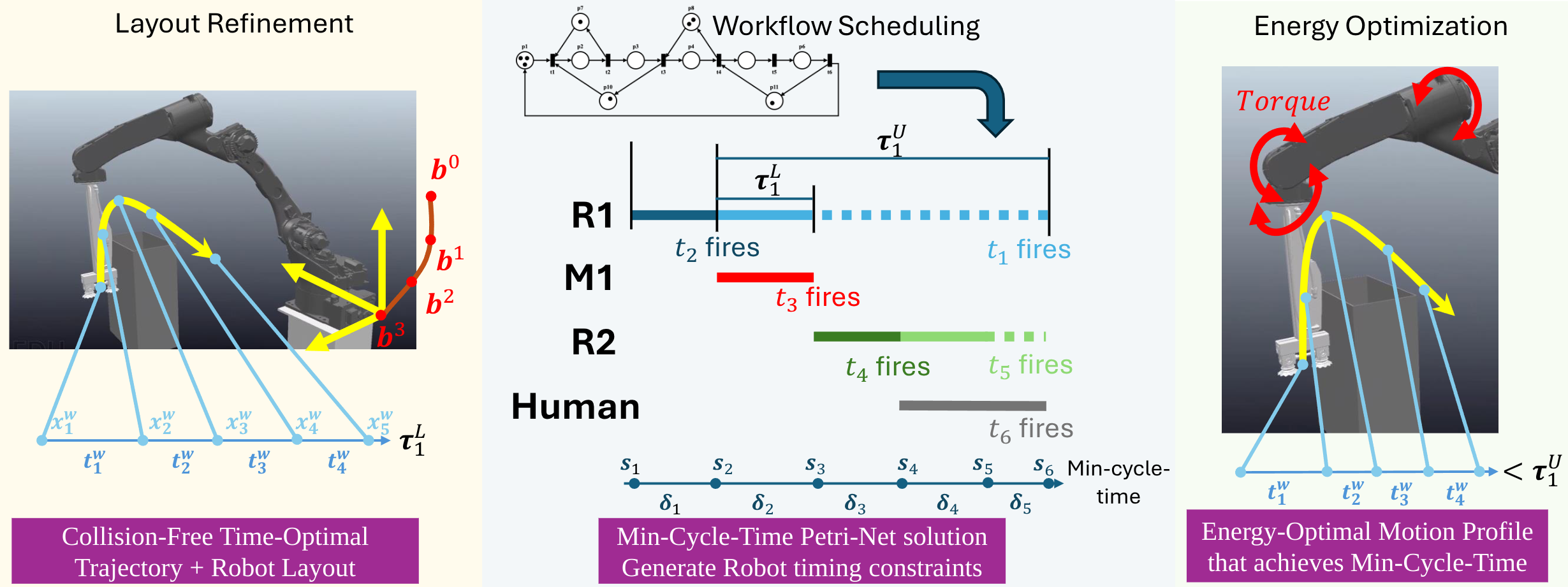

- Layout temporal optimization to find time-optimal trajectories

- Workflow scheduling to determine optimal task timing

- Energy optimization to reduce power consumption while maintaining cycle time

Key Innovations

Our work bridges the gap between robot-centric and workflow-centric approaches through three key innovations:

-

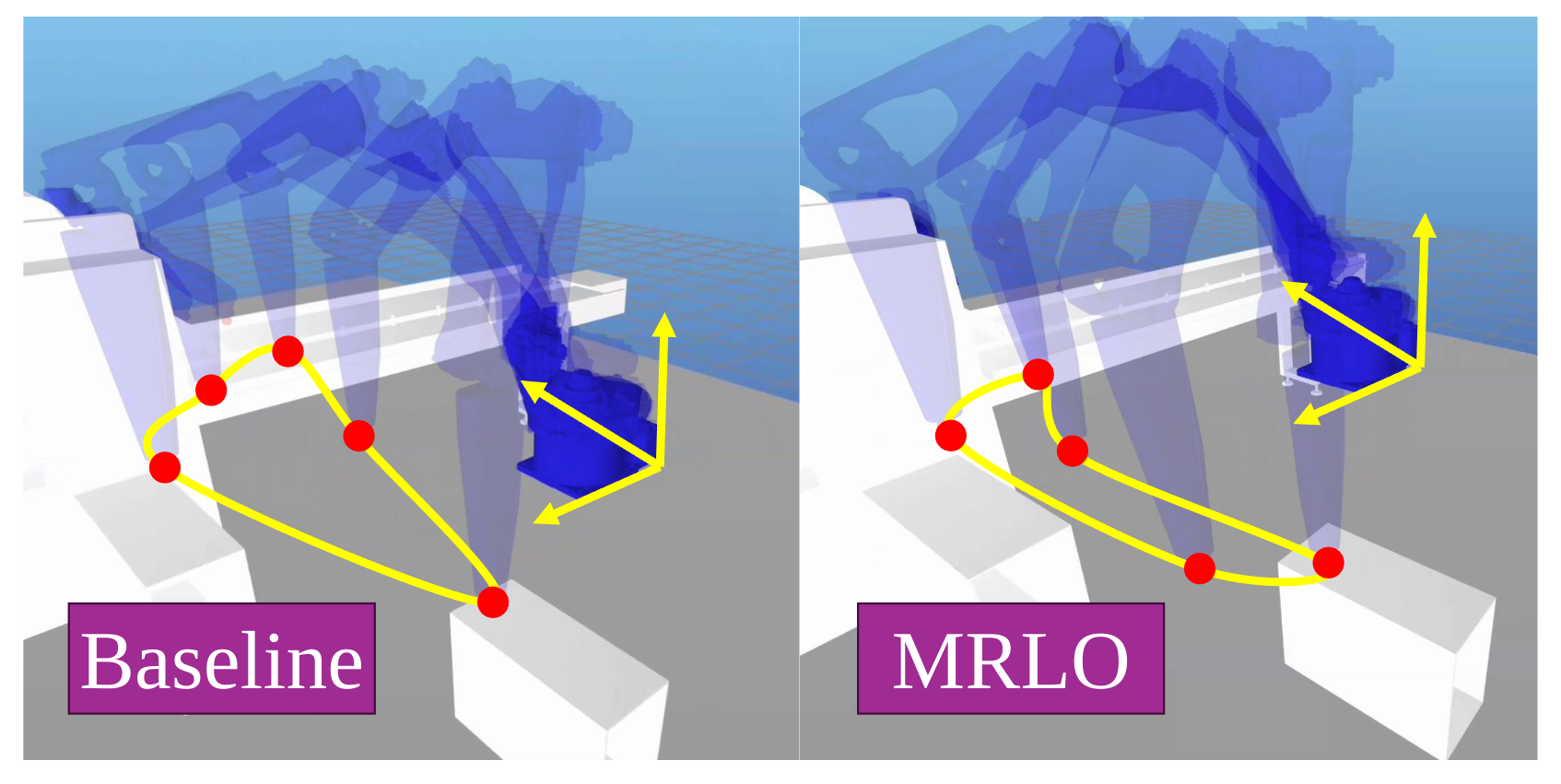

Integrated layout and trajectory planning: Rather than treating robot placement and motion as separate problems, MRLO allows robots to adapt their trajectories based on their relative positions.

-

Explicit payload dynamics modeling: The framework accounts for how carried objects affect robot performance, ensuring that layouts work well with actual payloads.

-

Two-level optimization: By combining global layout exploration with local trajectory refinement, the approach significantly speeds up the search process while finding high-quality solutions.

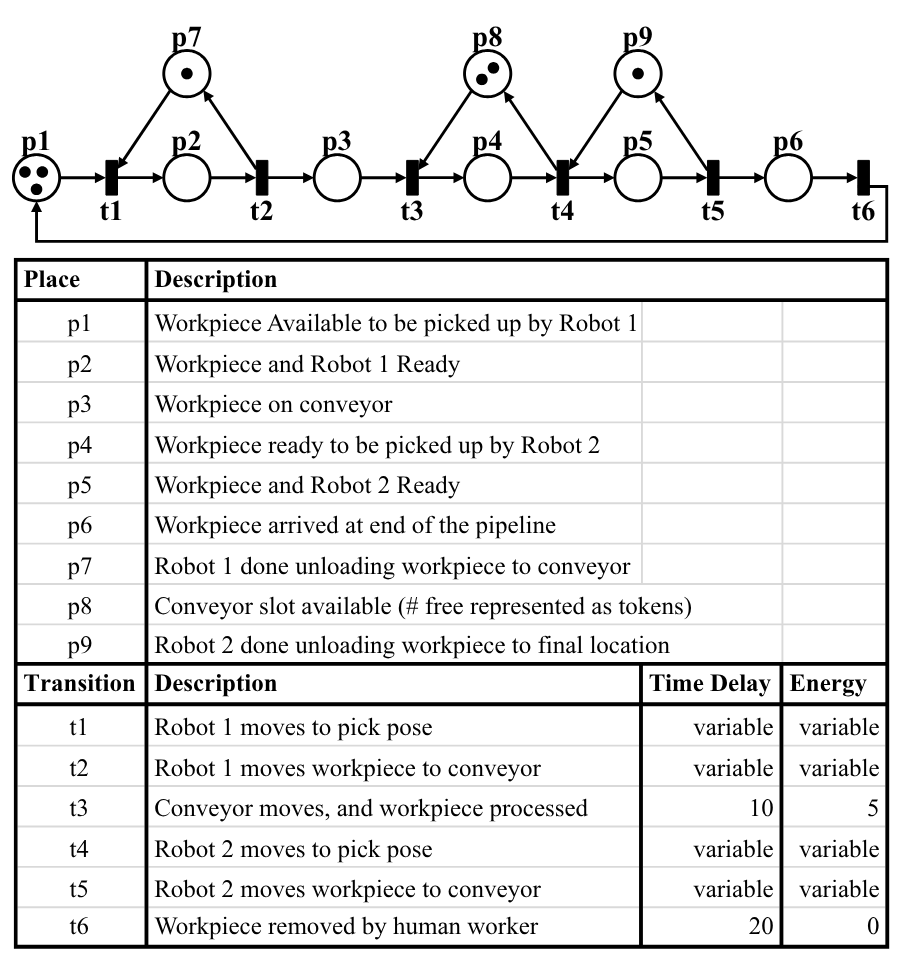

Intelligent Workflow Scheduling

One of the most impressive aspects of MRLO is its workflow scheduling component. Using a Petri net model of the production system, it not only determines when tasks should execute but also identifies which motions are on the critical path (those that directly affect cycle time) and which have timing flexibility.

This understanding enables a smart energy optimization phase where non-critical motions can be selectively slowed down to reduce energy consumption without affecting overall cycle time. The framework can also prioritize layouts that favor critical motions, leading to better overall efficiency.

Results That Matter

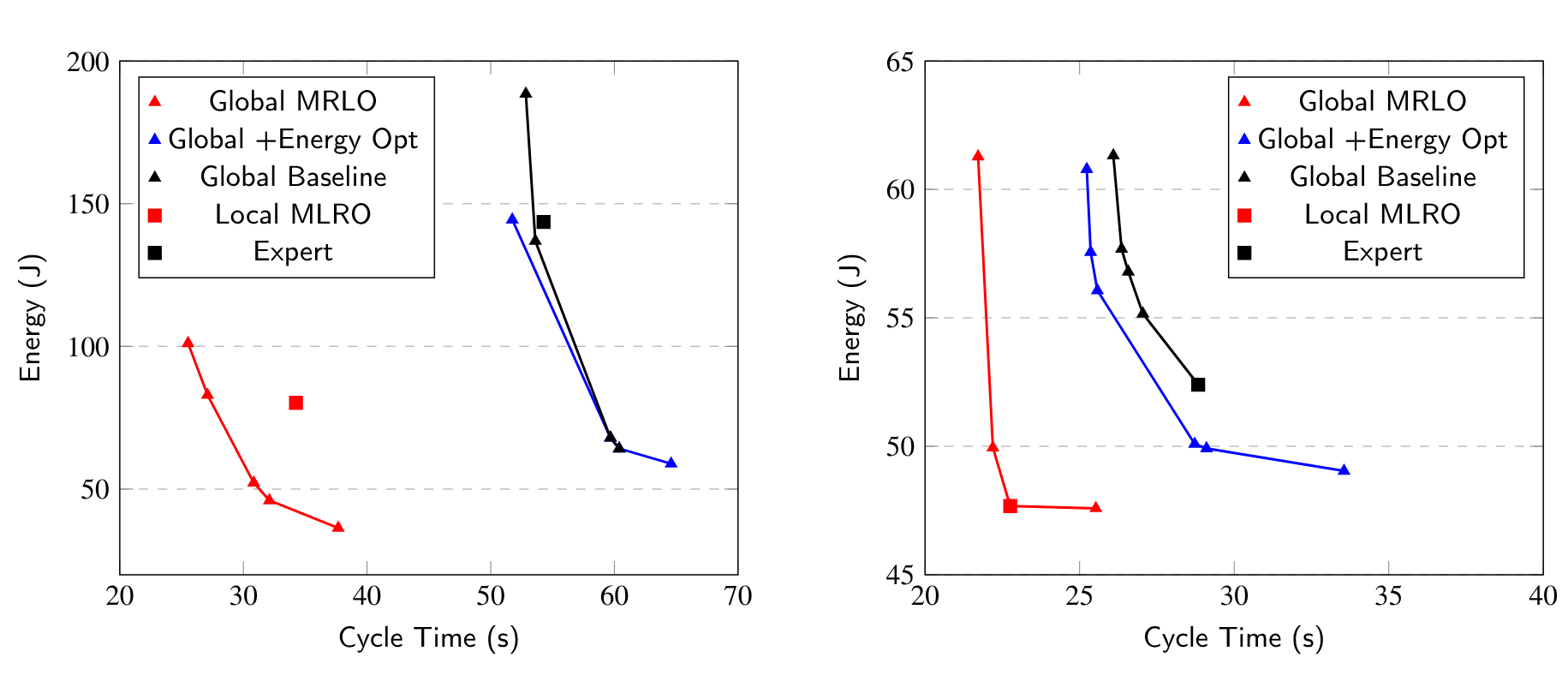

We demonstrated MRLO’s effectiveness through simulations of different production scenarios, including a two-robot sequential pipeline with conveyors and a parallel robot assembly line. The results showed substantial improvements in both cycle time and energy consumption compared to baseline approaches.

Even more impressive, these improvements were achieved with significantly fewer iterations than traditional methods, highlighting the efficiency of the two-level optimization approach.

As manufacturing continues to automate, optimizing robot layouts becomes increasingly important for maximizing productivity and minimizing energy consumption. The MRLO framework provides a powerful new tool for addressing this challenge, with potential applications in numerous industries from automotive manufacturing to electronics assembly.